Copyright © 2017-2023 All rights reserved. Designed and maintained by Oceans Media

The better the preparation, the better the Finish.

Gutterboys is very well known with architects, quantity surveyors, builders, engineers etc for our professional service and after sales service. We specialize in the supply and installation of seamless aluminium gutters and aluminium downpipes.

We have extensive experience in the design, fabrication and installation of domestic and industrial gutter. From houses of all sizes, small and medium sized malls, warehouses and large scale factories you can trust us to get it right, every time.

All our gutters are extruded on site, using one of our mobile factories. The gutters are extruded in continuous length, thus eliminating joins and therefore leaks. The aluminium is coated with a double coat of Polymer silicone enamel, baked on in high temperature ovens so that the paint becomes annealed to the aluminium. The product is guaranteed against rust, corrosion, peeling and flaking of paint.

ALUMINIUM GUTTERS

OGEE GUTTERS

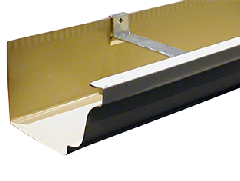

BOX GUTTERS

Aluminum gutters are lightweight and much easier to install than steel gutters and other materials that require joint soldering. Aluminum gutters ensure rust won’t be a problem and you get an effective seamless gutter system that will last. Steel is more durable but when leaves and other debris cause a downspout to clog this causes puddles which lead to rust. Aluminum doesn’t have this problem and gutters installed using aluminum usually last much longer than other systems.

Ogee Gutter is a shaped gutter profile adding a touch of design and aesthetic to your roof line. Ogee guttering has a double curved s profile and comes with a retaining clip pre-fitted for quick and easy installation. Due to its design and profile, it benefits from a high capacity, great for dealing with the climate in the Cape.

Box gutters are essentially placed between parallel surfaces, as in a valley between parallel roofs or at the junction of a roof and a parapet wall. They should not be confused with so-called valley gutters or valley flashings which occur at the non-parallel intersection of roof surfaces, typically at right angled internal corners of pitched roofs. Provision is made in the design of the gutter to have a rain flow to the outlet with a maximum slope of 1:200 and a minimum of 1:400.